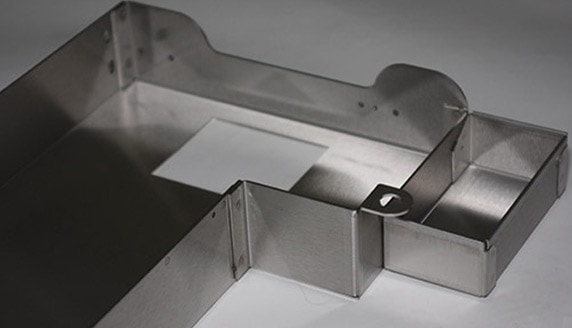

Fabrication of a Stainless Steel Tank Drawer

H&S Manufacturing is an industry leader in custom fabrications. This dental milling center project required various machining capabilities as well as part engineering and process design.

To fabricate this tank drawer assembly to the client’s specifications, we determined that utilizing our Amada LASMAC LC2415 2500 W laser would produce a stainless piece with a high-quality finish and appearance. This advanced capability allowed us to fabricate the large radius features on each end of the part without any tooling costs.

Constructed from ASTM-A240 and ASTM-A666 stainless steel, we utilized conventional fabrication processes including shearing, drilling, brake press forming, spot welding, and grain sanding. Once assembled, this tank drawer measured 21.811″ x 10.630″ x 3.047″.

As this is part of a dental milling center, the stainless steel surface was passivated per AMS 2700 Method 1, Type 2 standards. The finishing procedure removed surface contaminants and increased corrosion resistance.

Our quality measures included in-process dimensional and visual inspections. We upheld tolerances to the required ±.005″.

The following table outlines this fabrication project. For additional information, please feel free to contact us.

Email Us

Email Us