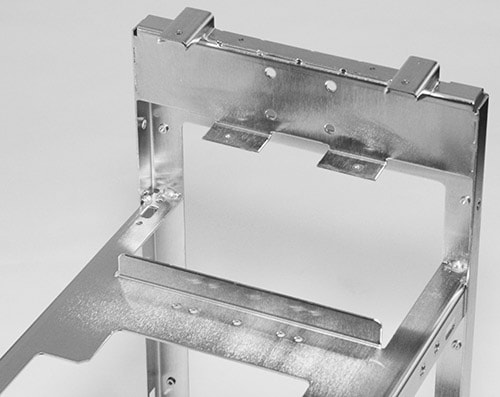

Fabrication of a Steel Cart Frame

At H&S Manufacturing we specialize in custom fabricated products for a wide range of applications. The project highlighted here was designed for use as a steel cart frame that is part of a computer chassis, used in the dental industry. Fabrication of this custom frame required our experience and knowledge of various CNC metal fabrication capabilities.

Per the customer supplied 2D CAD drawing and 3D model, we engineered the fabrication utilizing our state of the art equipment. Various shapes and sizes of parts were CNC punched from 1018 cold rolled steel and formed on the hydraulic brake press. Our extensive forming capabilities produced tabs and slots that were used in assembly. The components were welded together and several PEM nuts were inserted to complete the fabrication process. Final dimensions measured 22.250″ x 9.370″ x 14.420″. A zinc electroplated coating was applied per ASTM B633 standards, which increased corrosion resistance and provided a uniform finish.

Various quality measures were utilized to ensure dimensional integrity; this project received in-process gage inspections using an Amada Fabrivision and 24″ Brown and Sharp Microhite measuring device. We upheld tolerances to ±.005″ and met the customer’s exacting standards.

Additional information on this fabrication project can be found in the following table or by contacting us directly.

Email Us

Email Us