Industrial Sheet Metal Uses

Comments Off on Industrial Sheet Metal UsesIndustrial Sheet Metal Uses

H&S Manufacturing Co. is a leading provider of custom manufacturing solutions for a broad range of industries and applications. We specialize in precision sheet metal fabrication, machining, mechanical and electromechanical assembly, and testing. We are pleased to offer a variety of custom industrial sheet metal fabrication services to meet the particular needs of nearly any application.

Sheet Metal Fabrication and the Different Sheet Metal Forms

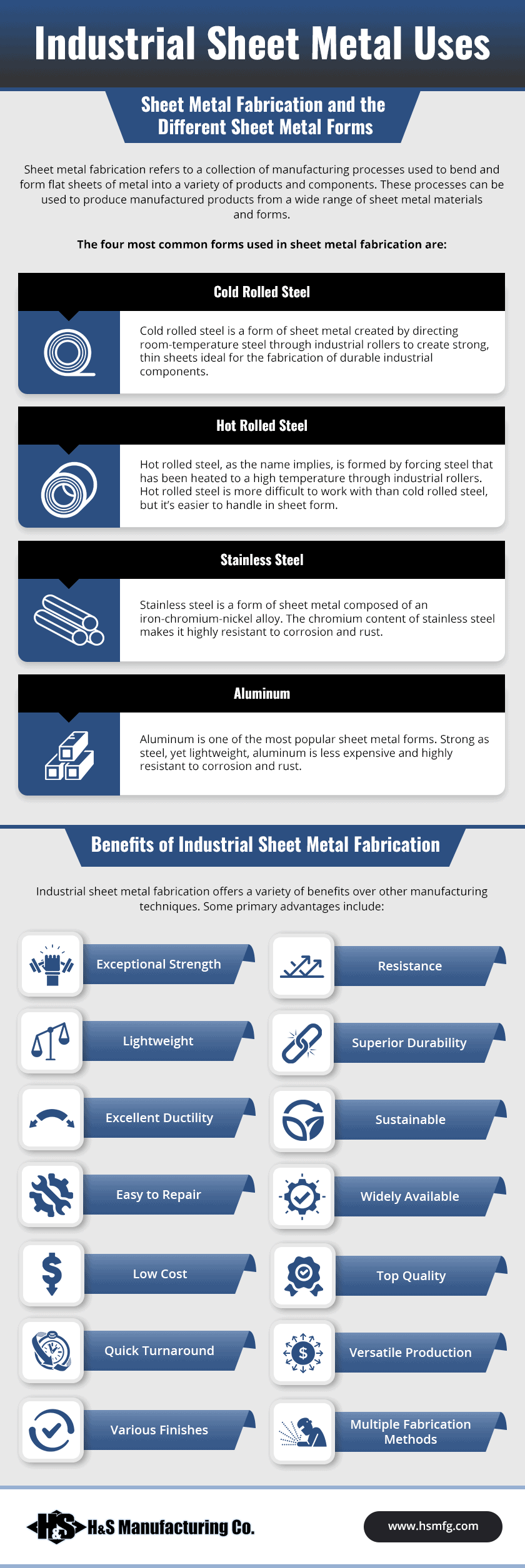

Sheet metal fabrication refers to a collection of manufacturing processes used to bend and form flat sheets of metal into a variety of products and components. These processes can be used to produce manufactured products from a wide range of sheet metal materials and forms.

The four most common forms used in sheet metal fabrication are:

Cold Rolled Steel

Cold rolled steel is a form of sheet metal created by directing room-temperature steel through industrial rollers to create strong, thin sheets ideal for the fabrication of durable industrial components.

Hot Rolled Steel

Hot rolled steel, as the name implies, is formed by forcing steel that has been heated to a high temperature through industrial rollers. Hot rolled steel is more difficult to work with than cold rolled steel, but it’s easier to handle in sheet form.

Stainless Steel

Stainless steel is a form of sheet metal composed of an iron-chromium-nickel alloy. The chromium content of stainless steel makes it highly resistant to corrosion and rust.

Aluminum

Aluminum is one of the most popular sheet metal forms. Strong as steel, yet lightweight, aluminum is less expensive and highly resistant to corrosion and rust.

Benefits of Industrial Sheet Metal Fabrication

Industrial sheet metal fabrication offers a variety of benefits over other manufacturing techniques. Some primary advantages include:

- Exceptional Strength. Sheet metal is valued for its exceptional strength. It is available in a variety of metals and alloys, so you can select the ideal strength for your particular application.

- Resistance. Sheet metals are available in a variety of materials that are resistant to corrosion, moisture, and UV radiation.

- Lightweight. Sheet metal is thin and light, which makes it easier to fabricate, transport, and store.

- Superior Durability. Sheet metal is formed using compressive force, which makes it highly durable and capable of operating in high-pressure conditions.

- Excellent Ductility. Sheet metal is pliable, which makes it ideal for use in fabrication processes that require exceptional precision.

- Sustainable. Sheet metal is made from natural metals and alloys that are non-toxic and easy to recycle.

- Easy to Repair. Sheet metal is easy to repair due to its high level of ductility and weldability.

- Widely Available. Sheet metal is a common material that is easy to obtain almost anywhere in the world.

- Low Cost. Since sheet metal is readily available and easy to transport, it is one of the least expensive manufacturing materials available on the market.

- Top Quality. Sheet metal is a high-quality material, making it suitable for creating a wide range of products.

- Quick Turnaround. Lead times for sheet metal fabrication are typically short.

- Versatile Production. Sheet metal fabrication processes are easily automated, which makes it easy to adjust production speed and volume as necessary.

- Various Finishes. Sheet metal can be finished using a variety of heat treatments, coatings, paints, and other finishing options, so you can choose the perfect finish for your needs.

- Multiple Fabrication Methods. There is an extensive selection of sheet metal fabrication methods that can be used to create quality metal products and components. Some of the most common fabrication methods include metal forming, cutting, welding, bending, and stretching.

Quality Industrial Sheet Metal Fabrication by H&S Manufacturing

Since 1968, H&S Manufacturing has been providing customers with superior precision products using the latest manufacturing and engineering technology available on the market. We use cutting-edge equipment to produce exceptional results for even highly complex parts within extremely tight tolerances. To learn more about our innovative industrial metal fabrication solutions, contact us today or request a quote.

Email Us

Email Us