Sheet Metal Design Guidelines: All You Need to Know

Comments Off on Sheet Metal Design Guidelines: All You Need to KnowSheet Metal Design Guidelines: All You Need to Know

In a day and age where fast production is the key to volume success, sheet metal fabrication has quickly become a key component of that process.

Sheet metal fabrication is essentially the mechanical process used to turn large portions of the material, like alloys, aluminum, and other metals, and turn them into smaller, more specific components of larger products.

Imagine turning a block of steel into military bullets. That’s what sheet metal fabrication can do for a variety of industries, from military and defense to lighting and home improvement.

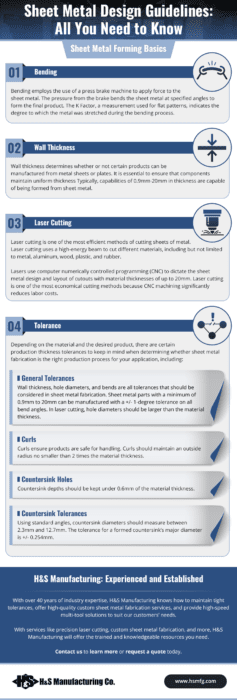

Sheet Metal Forming Basics

Sheet metal fabrication transforms metal sheets into different tangible parts through actions like punching, cutting, stamping, and bending.

3D CAD files are translated into machine code, which instructs a machine to accurately cut and shape the sheet into the final product.

Bending and wall thickness are two of the most essential things to consider before beginning the fabrication process

Bending

Bending employs the use of a press brake machine to apply force to the sheet metal. The pressure from the brake bends the sheet metal at specified angles to form the final product. The K Factor, a measurement used for flat patterns, indicates the degree to which the metal was stretched during the bending process.

Wall Thickness

Wall thickness determines whether or not certain products can be manufactured from metal sheets or plates. It is essential to ensure that components maintain uniform thickness Typically, capabilities of 0.9mm-20mm in thickness are capable of being formed from sheet metal.

When considering wall thickness, it is good practice to use a single sheet with punches as a determinant.

Laser Cutting

Laser cutting is one of the most efficient methods of cutting sheets of metal. Laser cutting uses a high-energy beam to cut different materials, including but not limited to metal, aluminum, wood, plastic, and rubber.

Lasers use computer numerically controlled programming (CNC) to dictate the sheet metal design and layout of cutouts with material thicknesses of up to 20mm. Laser cutting is one of the most economical cutting methods because CNC machining significantly reduces labor costs.

Tolerance

Depending on the material and the desired product, there are certain production thickness tolerances to keep in mind when determining whether sheet metal fabrication is the right production process for your application, including:.

- General Tolerances: Wall thickness, hole diameters, and bends are all tolerances that should be considered in sheet metal fabrication. Sheet metal parts with a minimum of 0.9mm to 20mm can be manufactured with a +/- 1-degree tolerance on all bend angles. In laser cutting, hole diameters should be larger than the material thickness.

- Curls: Curls ensure products are safe for handling. Curls should maintain an outside radius no smaller than 2 times the material thickness.

- Countersink Holes: Countersink depths should be kept under 0.6mm of the material thickness.

- Countersink Tolerances: Using standard angles, countersink diameters should measure between 2.3mm and 12.7mm. The tolerance for a formed countersink’s major diameter is +/- 0.254mm.

H&S Manufacturing: Experienced and Established

With over 40 years of industry expertise, H&S Manufacturing knows how to maintain tight tolerances, offer high-quality custom sheet metal fabrication services, and provide high-speed multi-tool solutions to suit our customers’ needs.

With services like precision laser cutting, custom sheet metal fabrication, and more, H&S Manufacturing will offer the trained and knowledgeable resources you need.

Contact us to learn more or request a quote today.

Email Us

Email Us