CUSTOM SHEET METAL FABRICATION SERVICES

What is Custom Sheet Metal Fabrication?

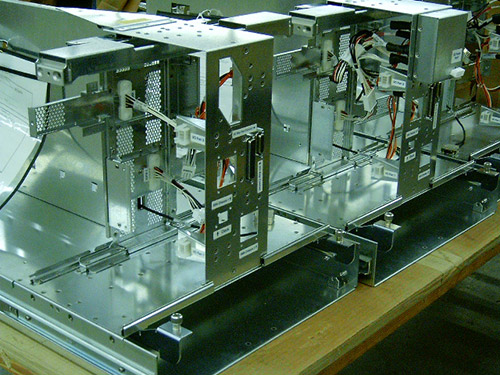

Custom sheet metal fabrication involves a wide range of equipment to cut, bend, and create complex metal assemblies and shapes. The most commonly used materials include sheets of stainless steel, carbon steel, aluminum, and copper in various thicknesses. Sheet metal is a common starting material for custom fabrication projects, as it is highly versatile and easily adaptable to the needs of diverse applications.

After a component’s design has been created and the necessary materials acquired, the fabrication work begins. Several techniques are typically involved in this process, including but not limited to:

- Cutting. Cutting can be performed manually, using handheld plasma cutters or power tools, or with automated processes such as laser cutting and waterjet cutting.

- Bending. Bending uses machines like press brakes to create U or V shapes in sheet metal.

- Welding. Welding involves fusing components together with high heat and pressure. Depending on the metal used, one of several types of welding can be used, including TIG, MIG, or arc welding.

- Grinding and graining. These processes are performed to create a uniform surface finish on sheet metal components. Typically, graining is performed before fabrication, with touch-ups after welding is completed.

- Hardware insertion. Rivets are drilled, punched, or placed into holes punched through the sheet metal, whereas hardware is inserted using Haeger presses.

After the sheet metal has been cut and formed into the desired shape, it is welded into position. To prevent warping or other abnormalities, many specialized welding techniques can be used. After the component is fully formed, sandblasting or other finishing processes might be performed, depending on the needs of the application.

Sheet Metal Fabrication Advantages

- Cost-effectiveness. The materials used in sheet metal fabrication have a long lifespan, featuring a high degree of durability and strength. This makes them highly cost-effective throughout the lifespan of the component. Additionally, sheet metal requires less tooling, as it can be cut and bent into shape quickly, which can also reduce costs.

- Strength and durability. Sheet metal fabrication uses stronger, highly durable materials that can withstand a great amount of pressure. Materials such as stainless steel and aluminum are also resistant to corrosion and hold up well in challenging environments.

- Malleability. The metals used in sheet metal fabrication are highly malleable, allowing them to be folded and shaped into endless design configurations while maintaining structural integrity.

- Replaceability. Making an assembly from multiple metal parts enables individual components to be removed and replaced if modifications or repairs are required. This is highly preferable to having to replace the entire component.

Sustainability. As a natural resource, metal is environmentally friendly and can be recycled indefinitely. In fact, the majority of certain metals, such as stainless steel, already come from previously recycled materials.

H&S Manufacturing offers high quality custom sheet metal fabrication services for clients in a broad range of industries, from lighting to medical and defense. Our AS9100D and ISO 9001:2015 registered facility specializes in prototype to full production volume, utilizing shearing, punching, graining, notching and extruding processes. This facility is equipped with modern high-speed multi tool equipment such as punch-laser machines, laser cutting machines, and punch presses. These capabilities allow us to produce parts from materials such as aluminum, cold and hot rolled steel, stainless steel, brass, and copper.

With over 50 years of experience we know how to maintain tight tolerances; for example, we hold a bend tolerance of ±.005″ hole to hole tolerance of ±.005″, hole to edge of ±.010″, and hole to bend of ±.015″ in material thicknesses of .015″ to .187″. Available finishing options include plating, silk screening and painting. We practice value engineering and efficiency methods and are dedicated to lean manufacturing. Specializing in customer service, we cater to client needs from consultation to finished product.

For more information on our custom sheet metal fabrication services, please see the table below or contact us directly.

Email Us

Email Us