INTERNATIONAL SHIPPING

H&S SPECIALIZES IN FAST, RELIABLE DELIVERIES

We ship to variety of locations including:

Since 1968, our goal is to ensure that customer satisfaction continues with on-time delivery at competitive prices.

Canadian Location

Capabilities

- Value-Added Assembly

- Precision Laser Cutting Services

- Custom Form in Place Gasket Services

- Mechanical Assembly & Value Added Assembly

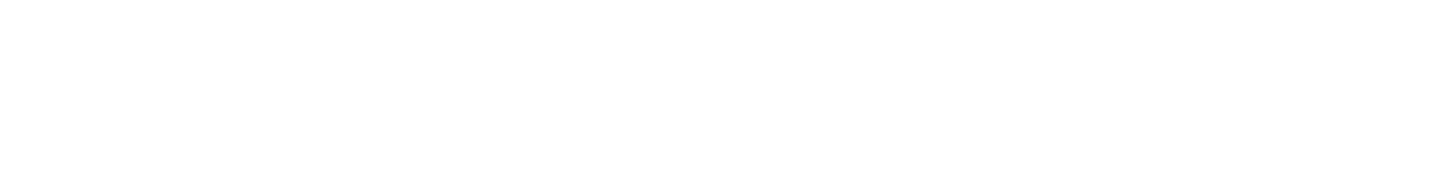

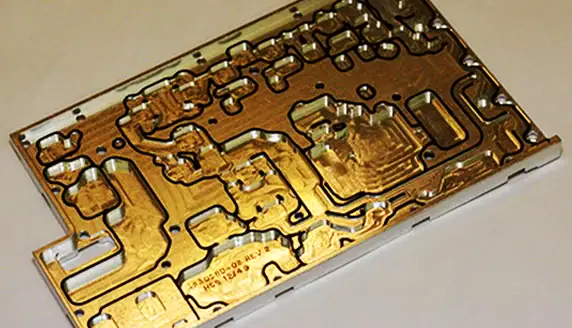

- Precision Machining Services

- Secondary/Finishing Services

- Custom Box Build Services

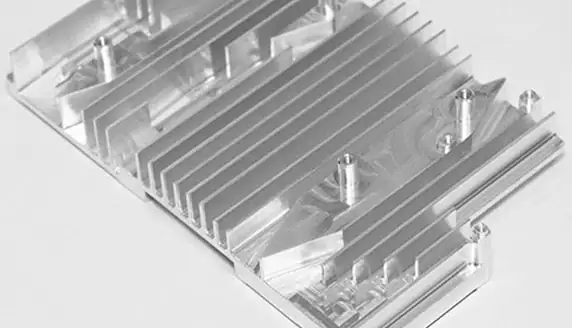

- Custom Sheet Metal Fabrication

- Laser Cutting Metal Services

- Precision Liquid Dispensing

- Powder Coating Services

- FIP Liquid Gasketing

Netherlands Location

Capabilities

- Value-Added Assembly

- Precision Laser Cutting Services

- Custom Form in Place Gasket Services

- Mechanical Assembly & Value Added Assembly

- Precision Machining Services

- Secondary/Finishing Services

- Custom Box Build Services

- Custom Sheet Metal Fabrication

- Laser Cutting Metal Services

- Precision Liquid Dispensing

- Powder Coating Services

- FIP Liquid Gasketing

Hungary Location

Capabilities

- Value-Added Assembly

- Precision Laser Cutting Services

- Custom Form in Place Gasket Services

- Mechanical Assembly & Value Added Assembly

- Precision Machining Services

- Secondary/Finishing Services

- Custom Box Build Services

- Custom Sheet Metal Fabrication

- Laser Cutting Metal Services

- Precision Liquid Dispensing

- Powder Coating Services

- FIP Liquid Gasketing

U.S. Location

Capabilities

- Value-Added Assembly

- Precision Laser Cutting Services

- Custom Form in Place Gasket Services

- Mechanical Assembly & Value Added Assembly

- Precision Machining Services

- Secondary/Finishing Services

- Custom Box Build Services

- Custom Sheet Metal Fabrication

- Laser Cutting Metal Services

- Precision Liquid Dispensing

- Powder Coating Services

- FIP Liquid Gasketing

Germany Location

Capabilities

- Value-Added Assembly

- Precision Laser Cutting Services

- Custom Form in Place Gasket Services

- Mechanical Assembly & Value Added Assembly

- Precision Machining Services

- Secondary/Finishing Services

- Custom Box Build Services

- Custom Sheet Metal Fabrication

- Laser Cutting Metal Services

- Precision Liquid Dispensing

- Powder Coating Services

- FIP Liquid Gasketing

Malaysia Location

Capabilities

- Value-Added Assembly

- Precision Laser Cutting Services

- Custom Form in Place Gasket Services

- Mechanical Assembly & Value Added Assembly

- Precision Machining Services

- Secondary/Finishing Services

- Custom Box Build Services

- Custom Sheet Metal Fabrication

- Laser Cutting Metal Services

- Precision Liquid Dispensing

- Powder Coating Services

- FIP Liquid Gasketing

Mexico Location

Capabilities

- Value-Added Assembly

- Precision Laser Cutting Services

- Custom Form in Place Gasket Services

- Mechanical Assembly & Value Added Assembly

- Precision Machining Services

- Secondary/Finishing Services

- Custom Box Build Services

- Custom Sheet Metal Fabrication

- Laser Cutting Metal Services

- Precision Liquid Dispensing

- Powder Coating Services

- FIP Liquid Gasketing

Sweden Location

Capabilities

- Value-Added Assembly

- Precision Laser Cutting Services

- Custom Form in Place Gasket Services

- Mechanical Assembly & Value Added Assembly

- Precision Machining Services

- Secondary/Finishing Services

- Custom Box Build Services

- Custom Sheet Metal Fabrication

- Laser Cutting Metal Services

- Precision Liquid Dispensing

- Powder Coating Services

- FIP Liquid Gasketing

China Location

Capabilities

- Value-Added Assembly

- Precision Laser Cutting Services

- Custom Form in Place Gasket Services

- Mechanical Assembly & Value Added Assembly

- Precision Machining Services

- Secondary/Finishing Services

- Custom Box Build Services

- Custom Sheet Metal Fabrication

- Laser Cutting Metal Services

- Precision Liquid Dispensing

- Powder Coating Services

- FIP Liquid Gasketing

Email Us

Email Us