PRECISION MACHINING SERVICES

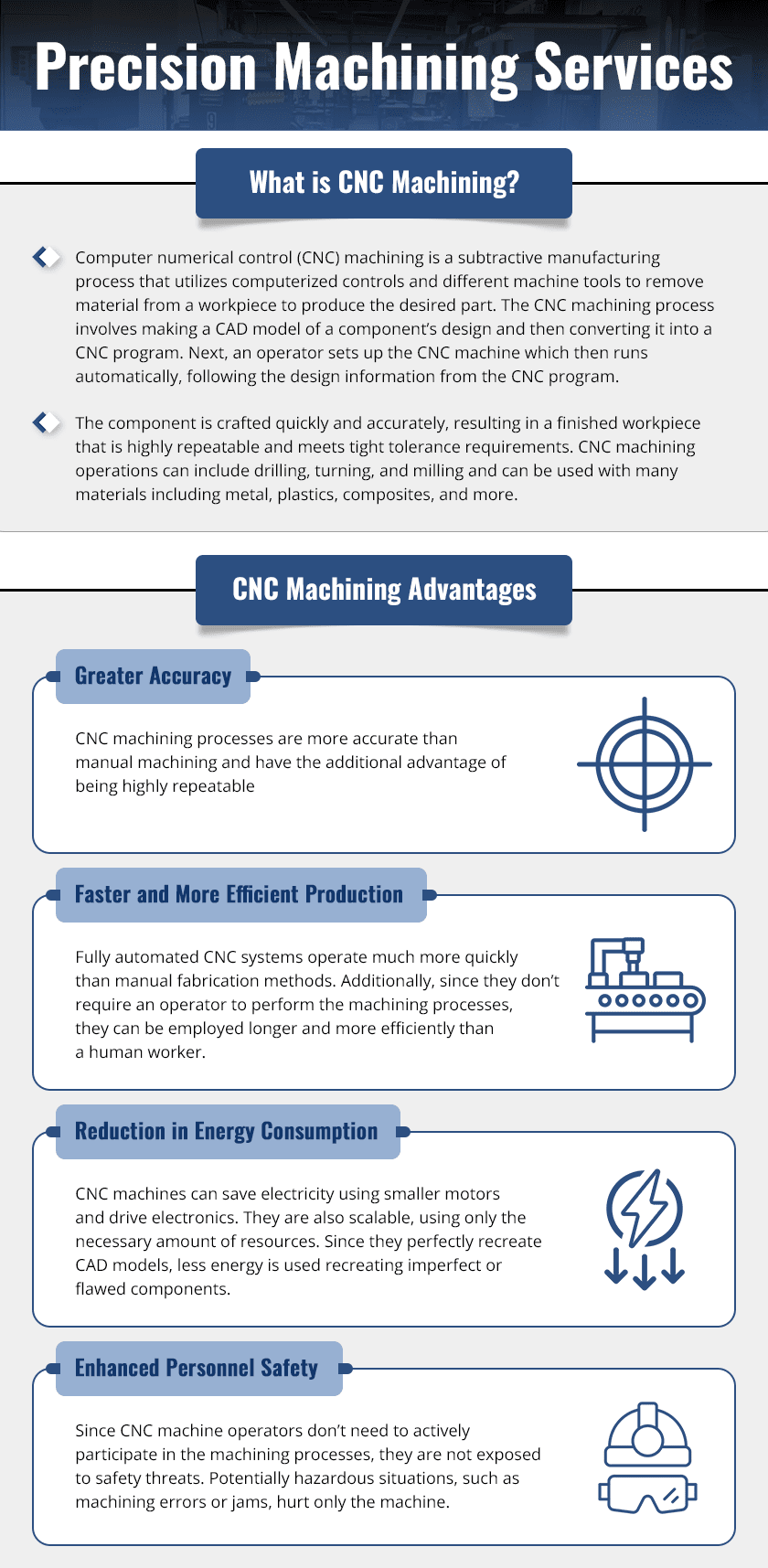

What is CNC Machining?

Computer numerical control (CNC) machining is a subtractive manufacturing process that utilizes computerized controls and different machine tools to remove material from a workpiece to produce the desired part. The CNC machining process involves making a CAD model of a component’s design and then converting it into a CNC program. Next, an operator sets up the CNC machine which then runs automatically, following the design information from the CNC program.

The component is crafted quickly and accurately, resulting in a finished workpiece that is highly repeatable and meets tight tolerance requirements. CNC machining operations can include drilling, turning, and milling and can be used with many materials including metal, plastics, composites, and more.

CNC Machining Advantages

- Greater accuracy. CNC machining processes are more accurate than manual machining and have the additional advantage of being highly repeatable.

- Faster and more efficient production. Fully automated CNC systems operate much more quickly than manual fabrication methods. Additionally, since they don’t require an operator to perform the machining processes, they can be employed longer and more efficiently than a human worker.

- Reduction in energy consumption. CNC machines can save electricity using smaller motors and drive electronics. They are also scalable, using only the necessary amount of resources. Since they perfectly recreate CAD models, less energy is used recreating imperfect or flawed components.

Enhanced personnel safety. Since CNC machine operators don’t need to actively participate in the machining processes, they are not exposed to safety threats. Potentially hazardous situations, such as machining errors or jams, hurt only the machine.

For over 50 years, H&S Manufacturing has been providing precision machining services for customers across a spectrum of industries. We specialize in the manufacturing of custom parts to exacting specifications utilizing our precision machining capabilities. These capabilities include milling, drilling, boring, tapping, and lapping, as well as welding, silk screening, plating, heat-treating and painting.

Our AS9100D, ISO 9001:2015 certified and ITAR compliant facility is equipped with advanced CNC machining equipment such as vertical and horizontal machining centers. We are able to handle materials such as aluminum, brass, copper, stainless steel, and hot and cold rolled steels in forms including coil, sheet, plate, bar, pipe and tube. Maximum size for machined parts is up to 24″ long x 24″ wide x 12″ high, machined to tolerances of ±.001 in (±.0254 mm). We handle volume from prototype to high production, with typical lead times of 6 weeks. For more about our precision machining services and our other value added capabilities please see the table below or contact us directly.

Email Us

Email Us