The Uses of Custom Sheet Metal in the Aerospace Industry

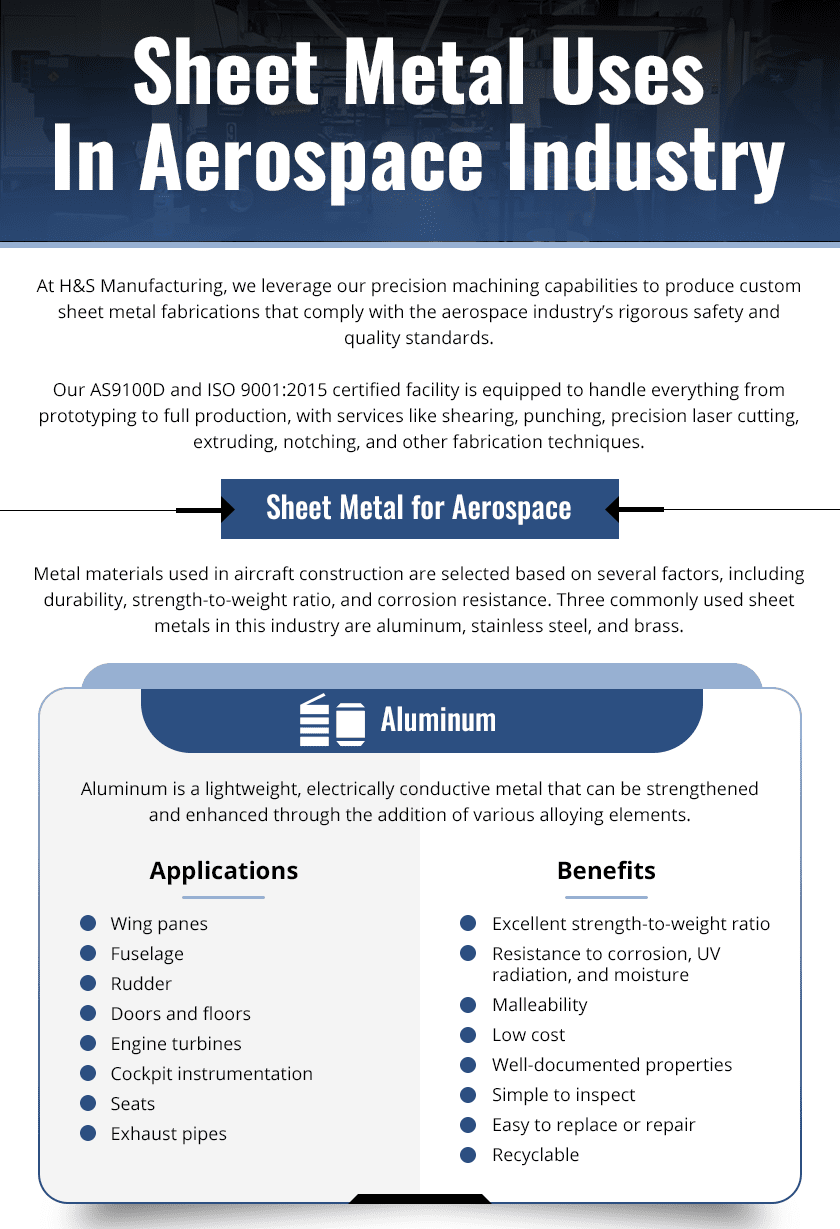

Comments Off on The Uses of Custom Sheet Metal in the Aerospace IndustryIn the aerospace industry, precision and consistency are critical to manufacturing and assembling safe, reliable aircraft. Aerospace parts must provide long-lasting performance while tolerating humidity, extreme temperatures, and high mechanical stresses. At H&S Manufacturing, we leverage our precision machining capabilities to produce custom sheet metal fabrications that comply with the aerospace industry’s rigorous safety and quality standards. Our AS9100D and ISO 9001:2015 certified facility is equipped to handle everything from prototyping to full production, with services like shearing, punching, precision laser cutting, extruding, notching, and other fabrication techniques.

In this blog, we’ll highlight the applications and benefits of our precision sheet metal fabrication services in the aviation & aerospace industries.

Sheet Metal for Aerospace

Metal materials used in aircraft construction are selected based on several factors, including durability, strength-to-weight ratio, and corrosion resistance. The metal’s structural integrity must also be capable of withstanding exposure to the high pressures and extreme temperatures encountered during flight. Three commonly used sheet metals in this industry are aluminum, stainless steel, and brass.

Aluminum: Aluminum is a lightweight, electrically conductive metal that can be strengthened and enhanced through the addition of various alloying elements. The most popular aluminum alloys in aircraft construction are 7075, 7475-02, and 6061, all of which exhibit excellent resistance to fatigue resistance and damage. Specific aerospace applications of aluminum sheet metal include:

- Wing panes

- Fuselage

- Rudder

- Doors and floors

- Engine turbines

- Cockpit instrumentation

- Seats

- Exhaust pipes

Stainless steel: Stainless steel is a group of corrosion-resistant iron-carbon alloys containing 10-30% chromium. Because they maintain superior mechanical properties over a wide temperature range, stainless steel alloys are ideal for enduring the harsh conditions of continuous flight. Applications of stainless steel sheet metal manufacturing in the aviation aerospace industry include:

- Airframes

- Landing gear

- Jet engines

Brass: Brass is a copper-zinc alloy with excellent hardness, workability, corrosion, and temperature resistance. This alloy performs well in harsh settings, making it ideal for aerospace environments. Applications of brass sheet metal manufacturing in aircraft construction include:

- Wheel and brake components

- Landing gear

- Cargo doors

- Casings for electrical components

Benefits

Aviation sheet metal fabrication is an intricate process that requires precision equipment and close attention to detail. Custom metal stamping and forming techniques are particularly well suited for sheet metal fabricated products since they allow for precise cutting and shaping while eliminating surface defects. Other benefits of metal stamping and forming include:

- Affordability: Metal stamping and forming are highly cost-effective, especially for large-scale production runs where the dies can be reused.

- Quick setup: With short setup times, metal stamping and forming processes ensure quick turnaround times for sheet metal manufacturing and fabrication.

- High accuracy: The custom dies and tools used for metal stamping ensure excellent precision and tight dimensional tolerances. Cold forming can achieve superior levels of precision since it eliminates any heat-related warping.

To maximize the benefits of sheet metal fabrication, it is important to choose materials that meet the functional and environmental requirements of a given aerospace application. Aluminum, stainless steel, and brass each have distinct advantages:

- Aluminum

- Excellent strength-to-weight ratio

- Resistance to corrosion, UV radiation, and moisture

- Malleability

- Low cost

- Well-documented properties

- Simple to inspect

- Easy to replace or repair

- Recyclable

- Stainless steel

- Corrosion resistance

- Generally stronger and more durable than aluminum

- Low maintenance

- Aesthetically appealing

- Brass

- Performs well at high temperatures

- Great conductor of heat and electricity

- Spark resistance

- Corrosion resistance

Sheet Metal Fabrication Services at H&S Manufacturing

For over 50 years, H&S Manufacturing has built employee trust, earned customer loyalty, and improved our sheet metal fabrication processes. By investing in the latest sheet metal manufacturing methods and equipment, we ensure cost-effective, compliant, and reliable sheet metal fabrications for a range of mission-critical aerospace applications. To complement our core manufacturing capabilities, we also offer secondary services to optimize your sheet metal fabricated products for their intended environment.

To learn more about our sheet metal fabrication services and other capabilities, please contact us today.

Email Us

Email Us