The Importance of Precision Medical Device Manufacturing

Comments Off on The Importance of Precision Medical Device ManufacturingThe Importance of Precision Medical Device Manufacturing

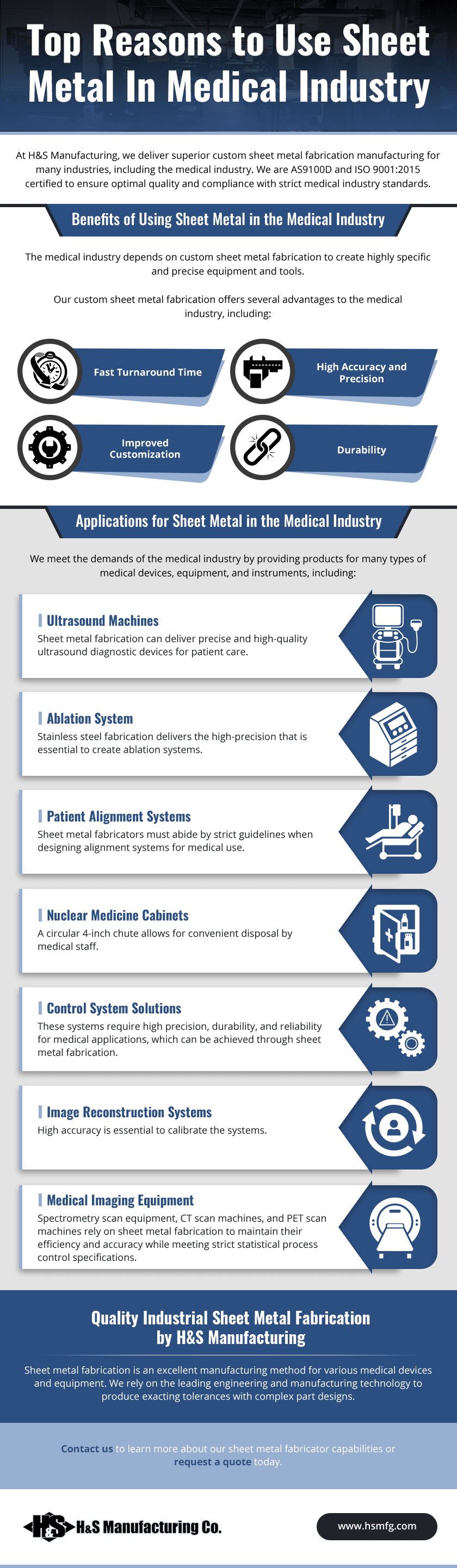

Medical instruments, equipment, and devices have strict specifications for materials, dimensions, tolerances, and finishing processes. They must be safe for critical healthcare applications and meet US and international standards in order to be brought to market.

Manufacturers serving the medical industry use several processes to achieve highly precise and accurate parts and components. Here, we’ll take a closer look at precision in medical manufacturing and some of the tools and operations used to achieve the highest quality components.

What Is Precision Manufacturing?

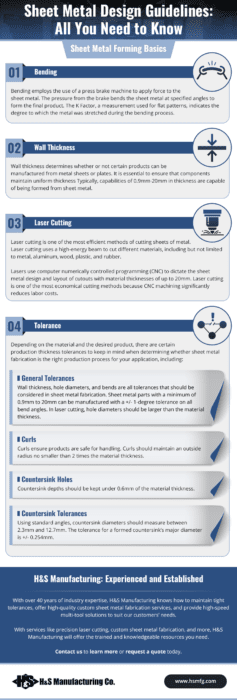

Precision is how closely parts match each other in terms of their finished dimensions. High precision means parts have little to no variation within a batch or production run. Achieving high precision is possible in manufacturing with computerized and automated equipment, such as laser cutting, programmable CNC equipment, and laser welding.

Ideally, components will also have a high level of accuracy, meaning the finished parts very closely match the design on the part print and correspond to dimensions and tolerances. Achieving both high precision and accuracy is the goal in medical device machining and manufacturing, regardless of the equipment and processes that are used.

The Importance of Precision Manufacturing for Medical Devices

Manufacturing for precision and accuracy is critical in medical applications to ensure proper function, long service life, patient safety, and compliance with regulations and standards.

Whether part of an assembly, instrument, enclosure, or other medical component, the more accurate it is, the better it will function in the real world. Likewise, higher precision makes it more likely that all finished devices or equipment in a batch or production run will function correctly.

Precision and accuracy come into play in every aspect of medical manufacturing. Some examples include removing small amounts of material to achieve hole diameters, forming proper bend angles and minimizing springback, or correctly locating welds in critical components. In most cases, the machines’ movements are controlled by computer programs. This makes each process highly repeatable and efficient because it avoids human fatigue, error, and variation.

Some examples include:

- CNC medical precision machining: Subtractive operations, such as drilling, boring, cutting, milling, or turning, remove material from a workpiece to achieve part features and dimensions. All movements, blade angles, and operations are based on a computer-aided drafting (CAD) file of the part that is translated into coded instructions the CNC machine follows over and over.

- Electromechanical Discharge Machining (EDM): An electrical discharge, or spark, between the electrode and workpiece creates thermal energy to remove material, forming complex or intricate shapes that are hard to achieve with standard CNC machining.

- Laser cutting: The high heat of the laser cuts through and vaporizes substrate material to form an exact shape. The laser can be programmed for accuracy and efficient material use. This process leaves a clean edge that requires little additional finishing.

- Laser welding: A high heat laser beam is concentrated to a small point to make accurate welds with a minimal heat affected zone (HAZ) on the material. It produces clean joints that rarely need additional grinding or polishing.

- Additive manufactured prototyping: A special printer deposits a stack of very thin layers of polymer or powdered metal to create a test model of a part. This is an effective way to test design functionality and identify possible points of physical stress or failure prior to full production.

Benefits of Using Precision Machining for Medical Devices

Advantages of precision machining include:

- Improved part uniformity: CNC and other computerized machining, laser cutting, and welding use the same operations and parameters on each cycle so there is very little variation between cycles.

- Enhanced speed, efficiency, and production volumes: High-speed equipment performs operations more quickly than a person can and does not become fatigued.

- Minimized human error: CNC machines use computers programmed with instructions so that all movements, cuts, and dimensions are consistent from part to part. This minimizes the risks of human error or inconsistency.

- Minimal waste: Computer-controlled manufacturing processes can be programmed to use material efficiently for less waste. Their high precision and accuracy also result in less scrap and rework.

Precision Machining for Medical Devices From H&S Manufacturing

At H&S Manufacturing, we work with a variety of tools and techniques for automated and semi-automated medical device machining, including CNC and EDM machining, laser cutting, laser welding, and additive manufacturing. Our capabilities also include mechanical and electromechanical assembly, sheet metal fabrication, and several secondary and finishing services.

Contact us to discuss your next medical device machining project or to request a quote.

Email Us

Email Us